X-tex fabric – an explanation of how it works (the long version)

X-tex is a polyester fabric with a polyurethane coating that is impregnated with activated carbon. It is fully waterproof with a hydrostatic head of over 20,000 mm and is highly breathable.

The key to what makes our X-tex fabric particularly effective in managing the condensation experienced in single-wall tents is the activated carbon within the coating. To understand why, we first need to understand the mechanisms of condensation, what happens to the water molecules, and how it can be managed.

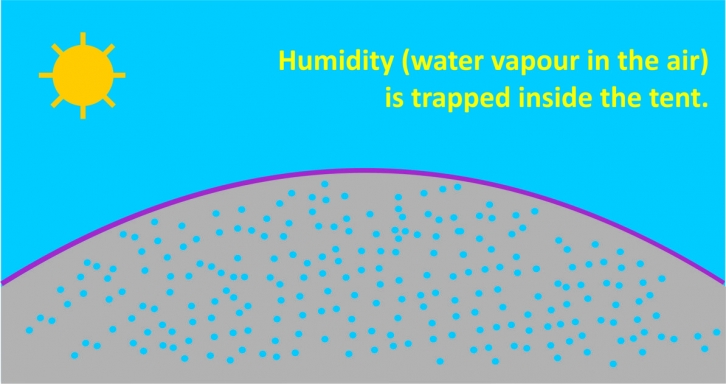

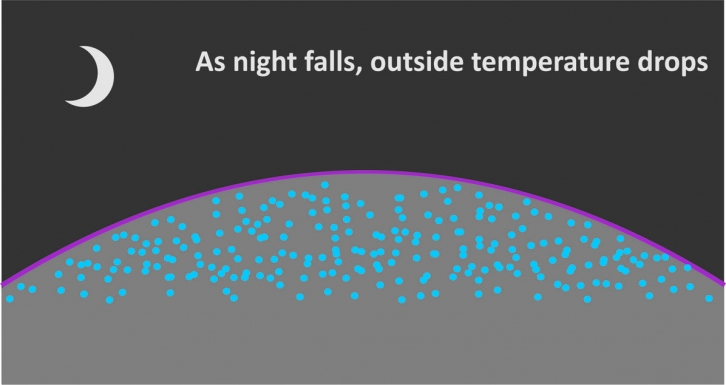

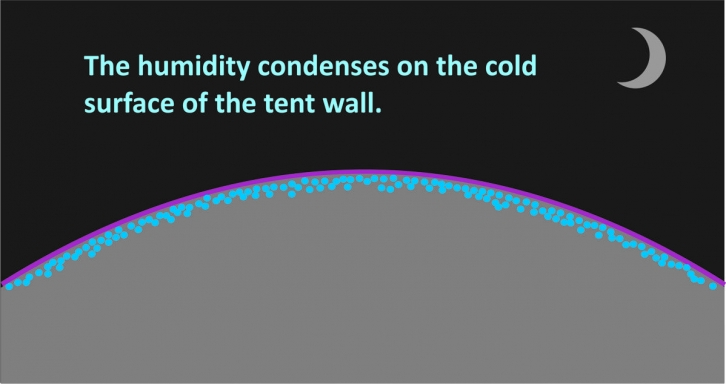

Humidity is trapped within the confines of the tent. It is always present in the air and also comes from body transpiration and activity such as cooking. The humidity is in the vapour state, where each molecule has a high energy level that prevents it from forming droplets. However, when the temperature drops outside, any humidity that comes into contact with the cold internal surface of the tent means it will immediately condense – in other words, lose its energy (known as the latent heat of vaporisation) and move from the vapour state to the liquid state. At this lower energy level, the water molecules can no longer overcome the attractive forces between themselves and form droplets.

In short, the problem is one of temperature (energy) and given that a tent is a small, warm body within a very large cold sink (the environs and atmosphere), it is impossible to prevent any humidity present from condensing on a cold surface.

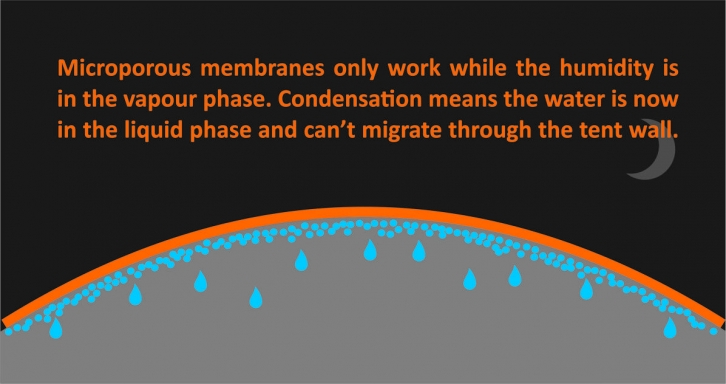

The second area we need to consider is what fabric technologies are available and how they work. Single-wall tents are made from either microporous or coated fabrics. In normal circumstances, as in waterproof clothing for example, these fabrics can be considered as “breathable”.

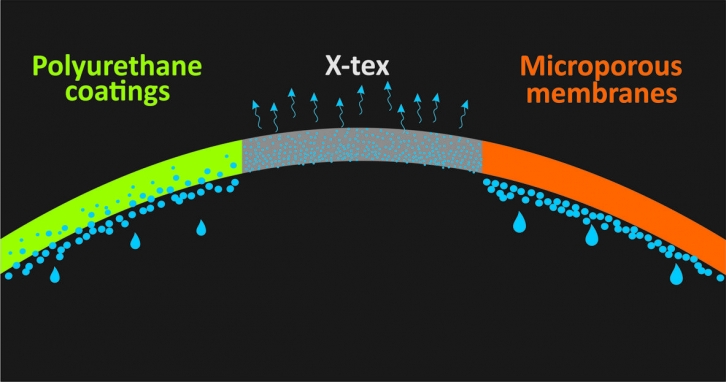

Fabrics with a microporous membrane (which includes PTFE-based examples such as eVent and Goretex) work on an osmotic process where there is a differential in pressure and/or molecule concentration, and individual molecules pass through until an equilibrium is reached between both sides. These fabrics only breathe whilst water molecules are in the vapour state. Once the humidity has condensed, and water droplets have formed (which is virtually instantaneous), these membranes can no longer breathe. The simplest explanation for this is that water vapour molecules are individual, small and have lots of energy and can physically fit through the microscopic pores of a membrane. Once condensation has occurred, the water molecules are in the liquid phase where they group together into large droplets, have a low energy state and cannot squeeze through the pores.

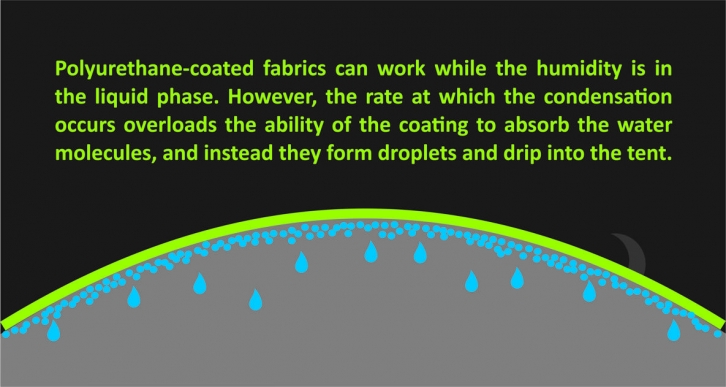

Fabrics with a coating (most typically polyurethane) work in a very different way. First, the coatings are, in most cases, monolithic. This means the coating is solid, or non-porous. (As an aside, there are also microporous polyurethane coatings, but the mechanisms and chemistry for breathability are the same). These fabrics work by chemically arranging the polyurethane molecules so there is a hydrophobic (water-hating) group at one end, and a hydrophilic (water-loving) at the other. One end pushes the water-molecules away, the other pulls (attracts) them. However, like microporous membranes, coated fabrics still rely on a humidity gradient – that is, there needs to be a higher humidity level on the inside of the tent than there is outside. In theory, this seems a much better choice of fabric (and it is), but the weakness in the process is that at the point of condensation, the liquefaction of the water vapour molecules happens too quickly. The polyurethane coating is unable to absorb all the water molecules, resulting in droplets forming on the inside of the tent.

In short, both fabric types rely on humidity gradients, but microporous membranes use temperature/pressure/energy (all the same thing) to “breathe”, whilst polyurethane coatings use the chemical forces of repulsion and attraction to “breathe”. Both fabrics are equally incapable of managing condensation.

Enter X-tex. As described, this is a fabric with a polyurethane coating, but with the special ingredient of activated carbon impregnated throughout.

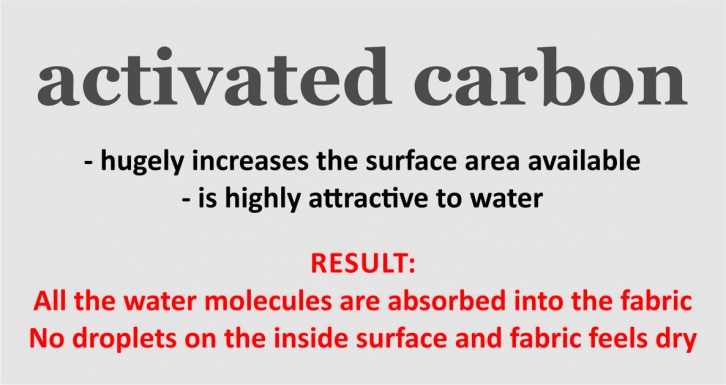

Activated carbon has two key properties that alters what happens to the water molecules at the point of condensation. First, it offers a greatly increased surface area at the microscopic level to enhance the adsorption rate of the water molecules. Secondly, activated carbon is very ‘attractive’ to water molecules. These two factors means that it literally sucks up all the moisture, almost as instantaneously as it condenses. This means that virtually all the water molecules are absorbed into the coating and are available for transportation to the outside, whilst at the same time, formation of water droplets are prevented.

There is one set of circumstances where no fabric will work, X-tex included, and this is in very cold conditions where the temperatures are so low that the water molecules not only condense, but freeze on the inside of the tent as well.